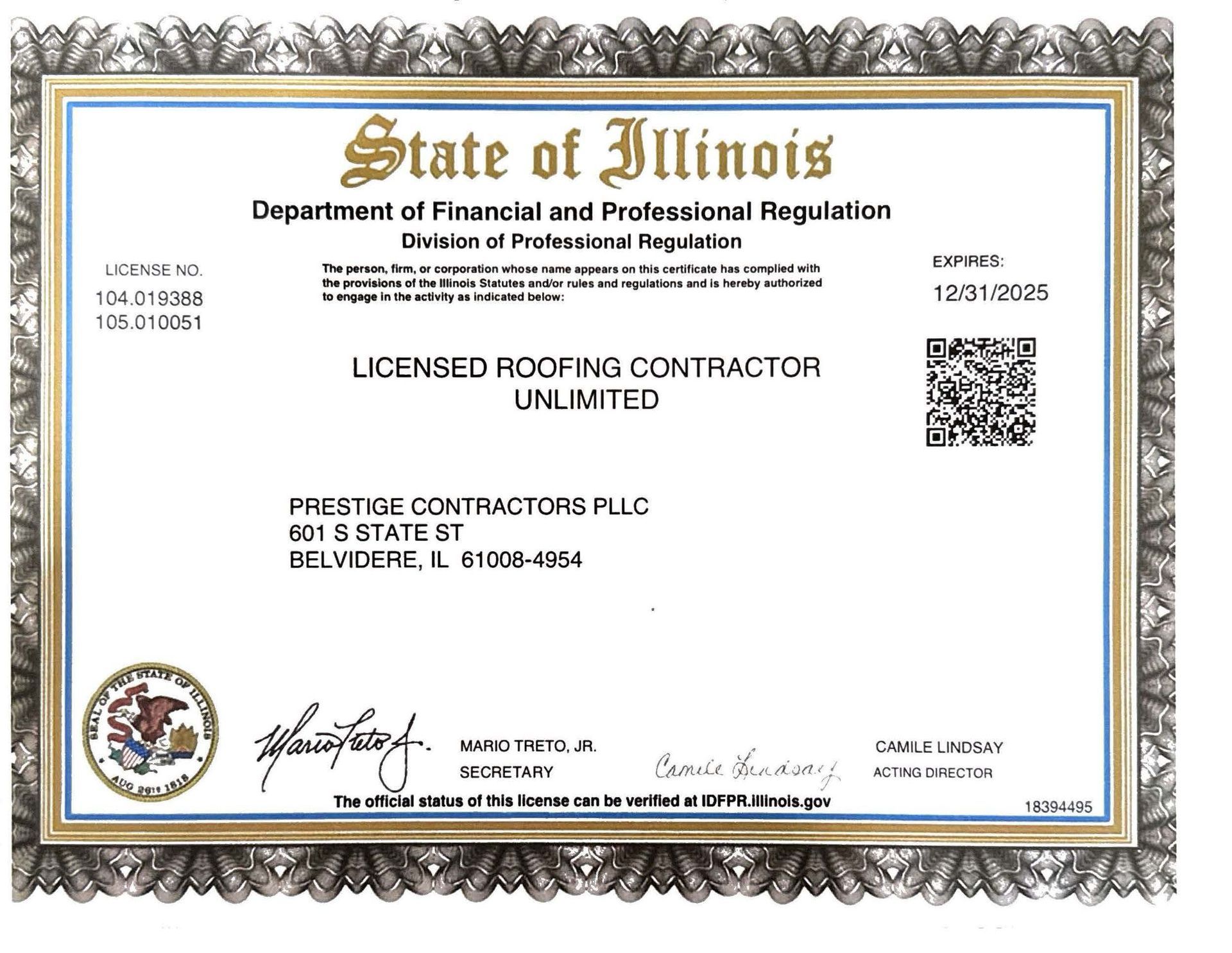

Prestige Contractors PLLC offers a comprehensive range of commercial roofing services tailored to meet the unique needs of businesses in Northern Illinois and the Chicagoland area. As a licensed, insured, and bonded company, we are committed to delivering high-quality workmanship and customer satisfaction.

Commercial Roofing

Licensed, insured, and bonded: ready to serve your business needs.

Popular Commercial Roofing Systems

TPO Roofing System

Short for thermoplastic polyolefin, TPO is a single-ply roofing membrane that offers excellent performance at a cost-effective price. Heat-welded seams provide superior strength. TPO's long-term heat, UV, and natural fungal resistance, plus flexibility without need for plasticizers also make TPO a reliable low-slope roofing system.

- Great Value: Excellent performance at a cost-effective price.

- Excellent Seam Strength: Heat-welded seams provide greater seam strength to taped and other seams

- Long-term Weathering: Excellent long-term heat and UV resistance

- Energy Saving: Highly reflective and emissive white surface can help reduce energy costs and urban heat island effect

- Inherently Flexible: No need for plasticizers

- Naturally Fungal Resistant: Doesn’t require biocides

- Versatile Application Methods: Including high-performance roofs requiring high wind uplift, increased puncture resistance, or quick economical systems.

PVC Roofing System

PVC has excellent flexibility. It also has increased resistance to UV, ozone, chemicals, tears, and punctures. That along with heat-welded seams, a white reflective color, and how simple it is to repair and install makes it the right choice for your job.

- Heat-welded seams for greater reliability.

- Easy, three-step installation to reduce the chance of application errors.

- High reflectivity for greater energy savings.

- Increased chemical resistance compared to other roofing technologies.

- Simple repair to reduce your ongoing maintenance costs.

Modified Bitumen BSB Roofing System

Modified Bitumen (MB) roofing is an asphalt-based, close cousin of the Built-up-Roof (BUR) designed for buildings with low-slope or "flat" roof structures.

Engineered modified bitumen roofing membranes originated in Europe in the mid 1960's and have been used successfully in the United States and Canada since approximately 1975.

Modified Bitumen Roofing Systems are designed to withstand harsh exposure to extreme environmental elements. With five layers of protection, it's one of the most trusted flat roofing systems used in the industry today.

- Proven track record of performance

- Superior waterproofing characteristics

- Broad range of application methods

- Wide choice of top-surfacing, including "Cool Roofing" options with insulation, provides an even better-performing building component

- High tensile-strength available as part of a fire, wind, and/or hail rated roofing system

- Competitive life-cycle cost available with flame-free and VOC-free installation

- Long-term warranties are available with many MB systems

Standing Steam Metal Roofing

Standing seam metal roofing panels are attached with concealed fasteners. Originally, clips engaged with the vertical legs and were used to attach the panel to the roofing substructure. As panel options have grown, however, it is common to see clipless panels included in this product family.

Standing seam systems are used for a wide range of applications and projects. These systems feature interlocking seams that connect panels, giving the roof a distinct, and attractive, appearance. Furthermore, standing seam systems are manufactured from high-end steel or aluminum offering years of low-maintenance service life.

Striations (also called stiffening ribs or rib rollers) are the “patterns” roll formed into a metal roofing panel between the seams. These can be used to assist with installing a metal roof, to help reduce the visibility of oil canning, or just for curb appeal. In fact, we recommend using striations in standing seam panels; some available options include:

- Flat – No indents between the seams

- Striated – Small, consistent indentation lines in the panel

- Ribbed – Shapes or indentations between the seams

- Clip relief – A stiffening rib adjacent to the seam that allows the space for a clip underneath

Elastomeric Roof Spray Coatings

An elastomeric roof is a liquid spray coating. It is typically made of acrylic resins and polymers, and titanium dioxide.

The liquid is typically sprayed on a roof to shore up any leaks or cracks. Another defining feature of elastomeric roofing systems is that they make the roof a monolithic structure. Such a structure means that the elastomeric layer is a single membrane that coats the entire roof.

- Waterproofing: One of the essential advantages of an elastomeric roof coating is that it adds a waterproof layer to new and old roofs.

- Versatile Application: You can apply an elastomeric coating to a new roof. Frequently, however, people opt for an elastomeric roof coating because their existing roof has leaks. Elastomeric coatings work to fill and shore up existing leaks on old roofs. They can be installed in almost any weather, too – adding to their versatility.

- Negate Re-roofs: Adding an elastomeric coating to your old roof is one way to negate the need for costly repairs or an entire re-roof. Be aware that not all roofs are good candidates for elastomeric coating as an alternative to a re-roof. In some cases, though, you can save a lot of time and money by simply adding an elastomeric coating.

- Save on Utilities: Because elastomeric coatings contain titanium dioxide pigments, they reflect UV light from your roof. UV reflection helps to keep your roof and your building cool when it’s hot. Typically, an elastomeric roof will help you cut down on your building’s cooling costs.

Request a Free Inspection/Estimate

Office

140 N. State St.

Belvidere IL, 61008

Phone

Office: 630-425-8757

Contact Us

We will get back to you as soon as possible.

Please try again later.